The Mhs - Material Handling Supply Inc. Ideas

The Definitive Guide to Mhs - Material Handling Supply Inc.

Table of ContentsGetting The Mhs - Material Handling Supply Inc. To WorkAn Unbiased View of Mhs - Material Handling Supply Inc.The 7-Minute Rule for Mhs - Material Handling Supply Inc.The 45-Second Trick For Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Can Be Fun For AnyoneUnknown Facts About Mhs - Material Handling Supply Inc.

This line is called the line of action. Forklift dealer. If the base of this line goes outside of the security triangle due to the fact that a tons is too hefty or too high, or due to the fact that the forklift is out a degree surface it will certainly topple. A vertical line expanding from the center of mass of the vehicle-load combination have to stay inside the stability triangular to avoid the forklift from tippingThe other principle to understand is the forklifts center of gravity. When unloaded, the forklifts center of gravity is appropriate about here.

Much heavier lots change the center of gravity ahead also further. Raising the tons additionally moves the facility of gravity forward. In order to stop the lift from tipping, the combined center of mass of the tons and the lift have to stay inside the stability triangle (at ground level) in all times.

Our Mhs - Material Handling Supply Inc. Ideas

If you have a balanced load, the load is unlikely to influence the side-to-side facility of gravity. https://mhsinc30677.start.page. However if you drive on a sloped surface area, your center of mass could pass beyond the security triangular and the lift can tip. Every forklift has an identification plate that provides essential info concerning the vehicle

To make sure that the facility of gravity of your forklift stays inside the stability triangle, don't try to lift anything heavier than the identification plate allows. No matter exactly how hectic you are, you need to evaluate your forklift prior to utilizing it. If you do discover something that can affect the safety and security of the lorry you have to report it right away.

Bear in mind, the operator is accountable for the secure operation of the forklift. If the forklift is utilized around the clock, examine it either before each change or after each change.

Mhs - Material Handling Supply Inc. - Questions

It is completed in 2 parts: the walk-around assessment, and, the seated inspection. OSHA does not require documentation of a daily assessment. Yet it's a good idea to have a checklist to ensure you do not miss any type of actions. These checklists can likewise be conserved as a component of the upkeep document.

Inspect the problem of the tires. If the forklift is an exterior forklift with pneumatically-driven tires, check the air pressure and search for extreme endure the tires. A tire with low atmospheric pressure might trigger the lift to tip when a tons is increased. So can a tire failing.

The 4-Minute Rule for Mhs - Material Handling Supply Inc.

Inspect the engine for any indicators of wear, loose links, or leaks. Look for splits or deformities in the forks, back-rest, mast, and overhead guard. Inspect the identification plate to make certain it is undamaged and readable.

Always start the engine while seated in the operator's positionnever while standing along with the forklift. Check all gauges and cautioning lights, and the battery or fuel level. Lift and lower the forks, and turn the pole.

Everything about Mhs - Material Handling Supply Inc.

Examine the brakes by dispiriting the brake pedal. Check the steering. Move the forklift ahead a couple of feet.

Leakages could suggest a hydraulic trouble, and liquids left on the floor are a slipping danger. Also try to find sparks or flames appearing of the exhaust system. Pay attention for any type of uncommon audios. If you locate anything wrong with the forklift during the walk-around or seated assessment, do not run it until it has been repaired.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

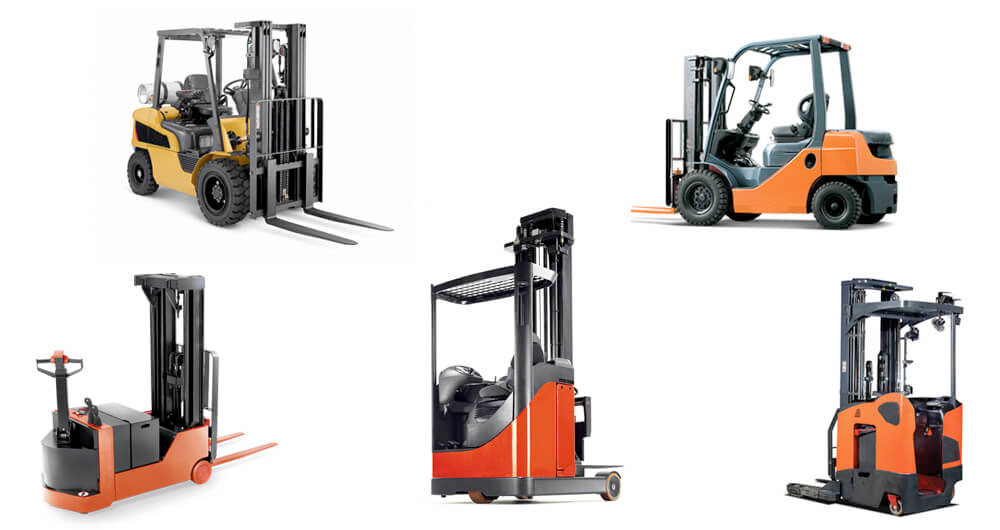

Forklifts have numerous moving parts and pieces that allow the forklift to run correctly. Understanding the terms of the components and composition of a forklift is necessary for reliable interaction with others while at work - https://www.4shared.com/u/crU-1WM2/tannergraves30677.html. Here are some of the fundamental functions and parts that make up the anatomy of a forklift truck

For many forklifts, the pole is created toward the front of a forklift and directly in the forklift driver's line of vision. Forklift masts come with discover here various areas that raise or lower the forklift carriage along with the forks.